PRODUCTS

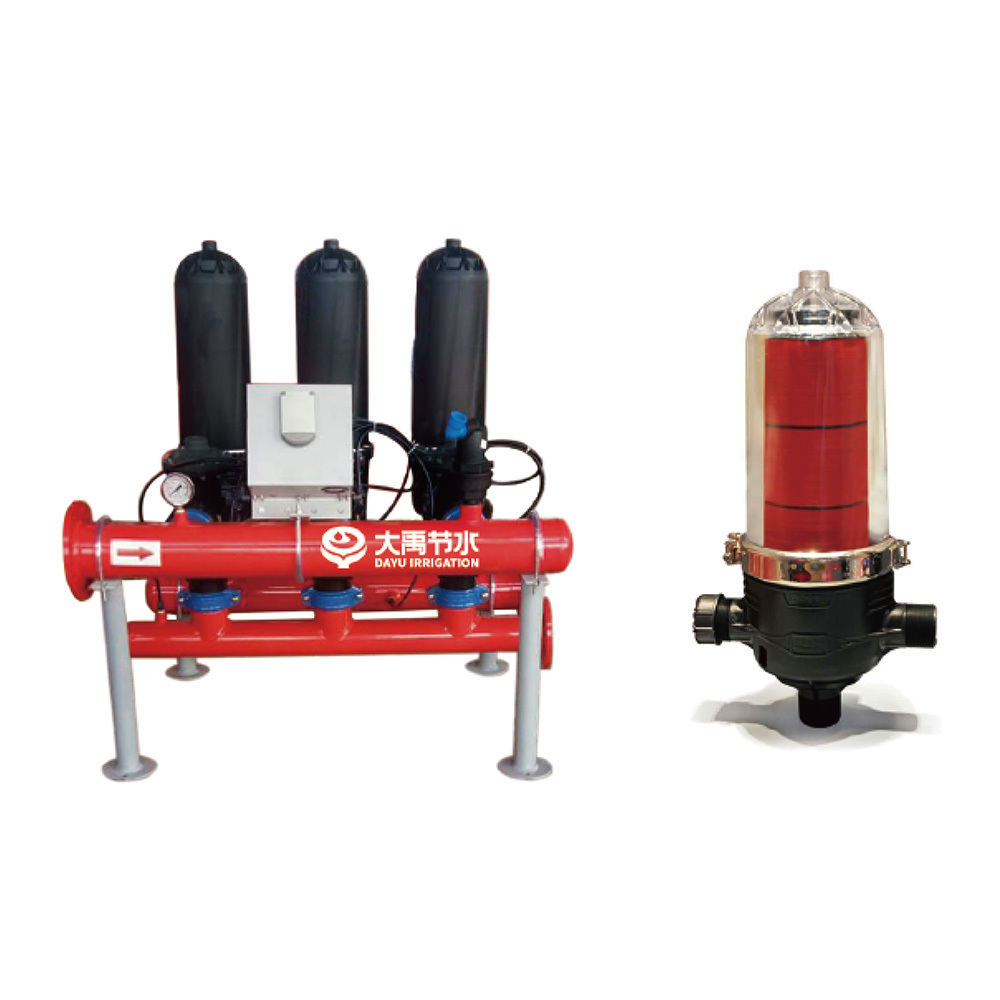

Sand Filter

The sand filter utilizes a sand bed of a certain thickness to remove organic and inorganic suspended solids from raw water. With its simple structure, proven technology, and high cost-performance ratio, it is widely used across various applications. The sand filter system can consist of one or more standard high-speed filtration units. Raw water passes through internal distributors, filter media layers, and collectors. By using the filter media, suspended solids are effectively removed and turbidity is reduced. (If specific filter materials such as activated carbon or anthracite are used, corresponding organic substances and harmful ions can also be adsorbed and removed.) The sand filter units are available in a wide range of standard sizes, from 16” (DN400mm) to 60” (DN1500mm). Custom non-standard units can also be provided according to customer requirements to create the most economical and practical combination. The sand filter can operate as an independent filtration system or as a side-stream filtration unit. When multiple units are installed on a shared pipeline, the system's filtration capacity can be infinitely expanded. It operates stably under high flow rates with low pressure loss, making it energy-efficient, environmentally friendly, and virtually maintenance-free.

Category:

Retail Consultation:

+86 19501968318 (Ms. Gao)

+86 19501968318 (Ms. Gao)

Retail@dyjs.com (Ms. Gao)

Project Consultation:

+86 19501990021 (Mr. Fu)

+86 19501990021 (Mr. Fu)

international@dyjs.com (Mr. Fu)

- Advantages

- Specifications

- Instructions for Use

-

- Commodity name: Sand Filter

The sand filter utilizes a sand bed of a certain thickness to remove organic and inorganic suspended solids from raw water. With its simple structure, proven technology, and high cost-performance ratio, it is widely used across various applications. The sand filter system can consist of one or more standard high-speed filtration units. Raw water passes through internal distributors, filter media layers, and collectors. By using the filter media, suspended solids are effectively removed and turbidity is reduced. (If specific filter materials such as activated carbon or anthracite are used, corresponding organic substances and harmful ions can also be adsorbed and removed.) The sand filter units are available in a wide range of standard sizes, from 16” (DN400mm) to 60” (DN1500mm). Custom non-standard units can also be provided according to customer requirements to create the most economical and practical combination. The sand filter can operate as an independent filtration system or as a side-stream filtration unit. When multiple units are installed on a shared pipeline, the system's filtration capacity can be infinitely expanded. It operates stably under high flow rates with low pressure loss, making it energy-efficient, environmentally friendly, and virtually maintenance-free.

Product Advantages

Filter Performance Features

- The filtration system adopts a modular design. Multiple filter units are available for flexible combination based on required flow rate and space.

- The backwash system is simple and requires no backwash pump. It is easy to operate and ensures consistent filtration performance.

- The filtration system automatically initiates backwash based on time, pressure differential, etc. It operates fully automatically, with each unit backwashed in sequence without interrupting water production.

- Even distribution of nozzles ensures uniform water distribution, no dead angles during backwash, high backwash efficiency, short duration, and low water consumption.

- Skid-mounted tank for easy installation without lifting equipment.

- Compact system footprint. Filter units can be flexibly arranged based on actual site conditions.

- Lightweight system requires no special foundation; standard concrete is sufficient.

Structural Features of the Filter Unit

- Quick-open manhole cover allows for fast and easy access.

- Socket-type filter nozzles with simple structure, high strength, easy installation, and reliable fixation.

- The filter shell is manufactured on an automated welding line, ensuring uniform quality and high pressure resistance.

- Both the inner and outer surfaces of the filter tank and piping are coated with electrostatic powder, resistant to sewage corrosion and UV radiation, suitable for outdoor installation.

Application Scope

- Suitable for treating river water, reservoir water, channel water, lake water, or municipal recycled water with organic content over 10mg/L and large amounts of suspended solids. Commonly used as a primary filter.

-

Specifications

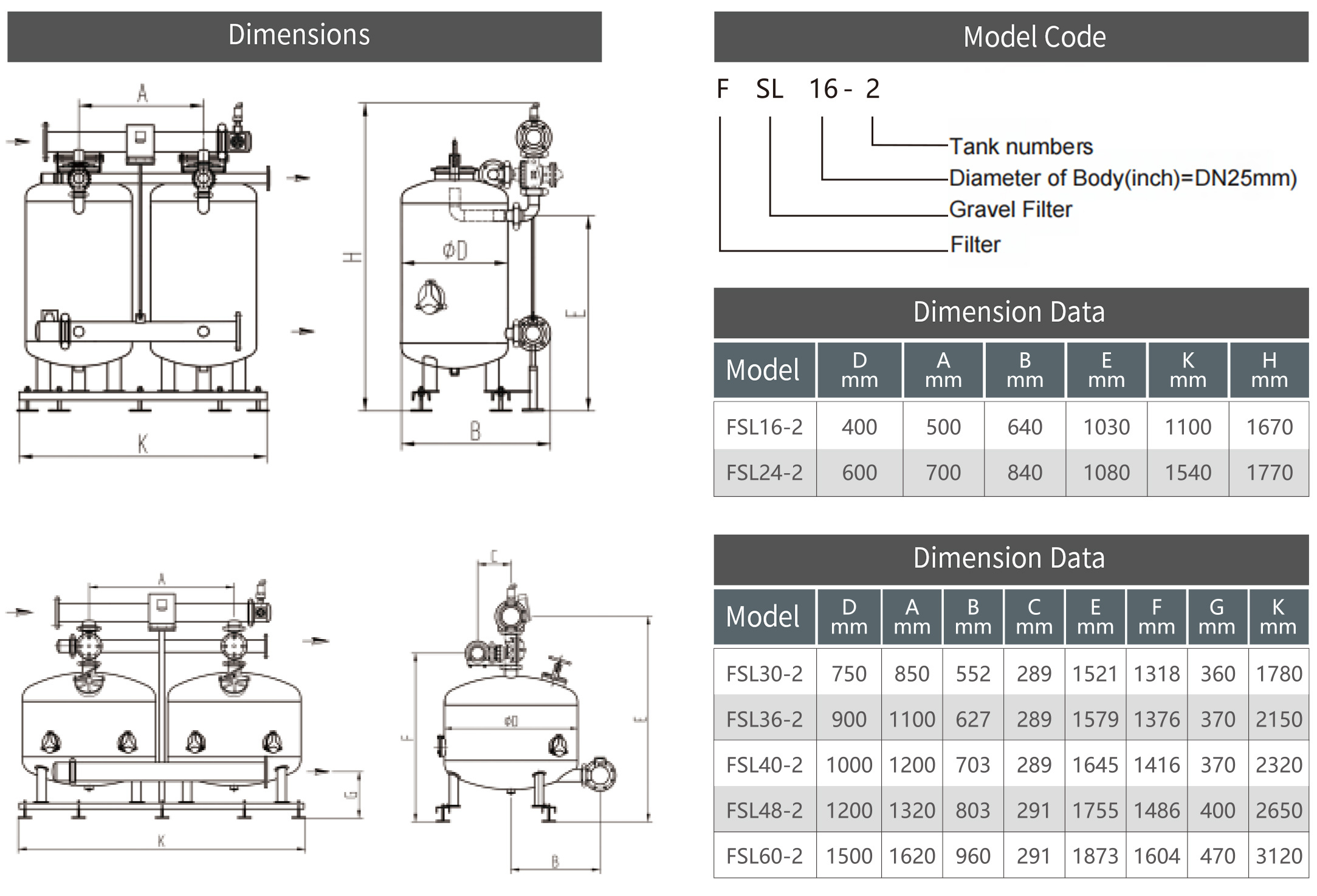

Model

Number of Tanks

Standard Flow Range

Filtration Area (m²)

Backwash Flow (m³/h)

Media Amount (kg), Sea Sand 1–2mm

Max Pressure (MPa)

Inlet/Outlet Size

Drain Pipe Size

Weight (kg)

Min Flow (m³/h)

Max Flow (m³/h)

FSL16-2

2

12

20

0.26

10

220

1.0

3”

3”

140

FSL24-2

2

30

50

0.58

20

500

1.0

3”

3”

216

FSL30-2

2

30

70

0.91

35

640

1.0

4”

4”

318

FSL36-2

2

60

100

1.31

45

920

0.8

4”

4”

400

FSL40-2

2

90

130

1.62

65

1120

0.7

6”

6”

512

FSL48-2

2

100

180

2.32

80

1600

0.6

6”

6”

650

FSL48-3

3

150

270

3.48

80

2400

0.6

6”

6”

975

FSL48-4

4

200

360

4.65

80

3200

0.6

8”

8”

1300

FSL48-5

5

250

450

5.81

80

4000

0.6

8”

8”

1760

FSL48-6

6

300

540

6.97

80

4800

0.6

8”

8”

1950

FSL60-2

2

160

220

3.64

130

2500

0.6

6”

6”

972

-

Instructions for Use

1. The tank features a double-layer internal structure. The upper section above the filter plate contains the sand bed and space for impurity retention, while the lower section serves as the clean water circulation zone. A drain outlet is reserved at the bottom of the tank to remove any sediment that may accumulate.

2. The effective particle size of the quartz sand is 0.4–1.2 mm.

3. The tank can withstand a maximum pressure of 10 kg/cm². Higher pressure-resistant tanks can be customized upon request.

4. The interfaces are available in both flange and clamp types for easy assembly.

Related products

Related products